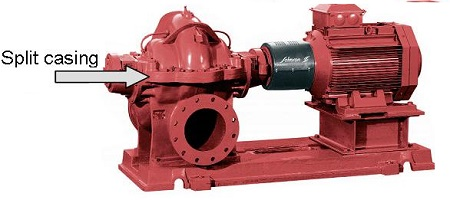

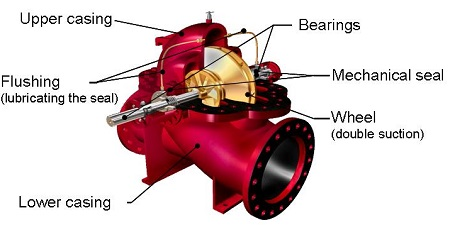

For very high flow rates, and in order to have easy access to parts likely to be replaced, there are pumps whose upper casing can be removed.

We speak of split casing pumps. The split casing separates the upper casing from the lower casing.

These pumps are

most often used for pressure boosting and irrigation (open circuits) for very

high flow rates which can exceed several thousand [m3 per hour].

They are also used for urban heating installations.

Other particular characteristics:

- A double entry impeller which decreases the risks of loss of pump-priming and cavitation(*).

- Part of the discharge fluid is extracted and “recycled” directly onto the mechanical seals to facilitate lubrication.

(*) Cavitation

is the formation of vapour cavities in a liquid. It usually occurs when a

liquid is subjected to rapid changes of pressure that cause the

formation of cavities where the pressure is relatively low.

When subjected to higher pressure, the voids implode and can generate an

intense shockwave which can destroy the impeller.