Standard norm pumps and in-line pumps which are too

heavy for the pipes are installed on concrete blocks.

They are fixed using a base plate of steel or cast iron, which is itself

screwed to the block by mounting studs.

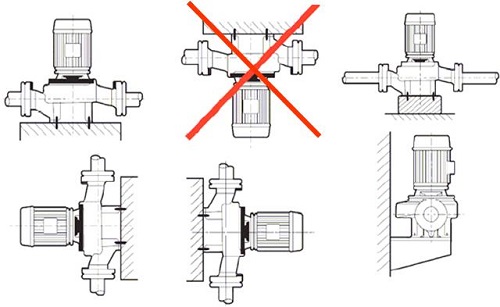

Depending on the design of the pump, the motor can be installed horizontally or

vertically.

Examples:

The mounting

position with the drive shaft horizontal is authorized up to a nominal power of

15 [kW]. Mounting with the “motor downwards” is not authorized.

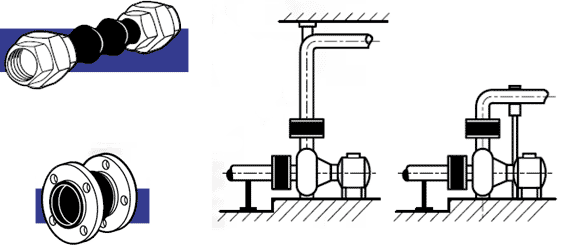

Pumps can be mounted between 2 anti-vibration sleeves or cylinders and

expansion joints.

These are composed of two union connections and two flanges, linked together by

elastomers or a metallic structure which can:

- Absorb the possible vibrations preventing them from spreading to the rest of the installation

- Allow expansion of the pipes without creating constraints

Source la Robinétique

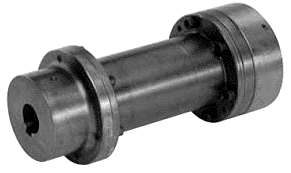

To be able to access the different elements of pumps equipped with very heavy electric motors, without having to dismantle them from their base, a special coupling exists which includes a “spacer” part.

The spacer coupling allows the hydraulic unit to be removed without disassembling the motor and without dismantling the pump from the pipe.