For training at PB level, this section and the others will not be studied.

Air Handling Unit fans are often driven by belt pulley mechanisms.

The

risk of the fan drive belt breaking is something that needs to be

taken into account, otherwise the electric motor will run without any

power load.

Note:

consult the section on fan belt-pulleys to see maintenance of fan

drive belts.

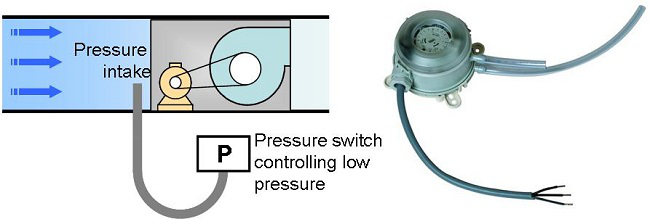

In order to avoid the drive belt breaking, the outer casing of the fan is usually fitted with a pressure control switch monitoring the suction rate at the fan air inlet, sign of its good working order.

Detection of unusually low vacuum pressure (or none at all) will stop the motor and set off an alarm.

It is also quite possible of course to connect this action to the closing of one or more other functions, or the stopping of another fan, etc.

An ambiguity to be noted: if the pressure switch detects unusually low vacuum pressure (or none at all) it will stop the motor. How then is it possible to re-start the motor with the vacuum pressure at zero?

In fact, the action of the pressure control switch is on a time delay.

The pressure switch will only stop the motor if it registers an abnormally low pressure 10 to 60 seconds after the starting of the motor.

The connection is said to be on time delay mode. This delay can generally be regulated.

Note : When the fan motor is controlled by a variable speed drive, the time delay should be related to the ramping up time to full capacity.

Question

If you know of one, give an example of a control function which should be time delayed to enable the starting or re-starting of a machine.

Example 1 :

The running of a pump motor can be determined by the effective detection of a flow rate controlled by a flow switch.

To be able to start the motor this control function is time delayed. If the pump is switched on inadvertently when a cut-off valve has been closed in the system, it will switch itself off after a dozen or so seconds and will thus be protected.

Example 2 :

To avoid a short circuit in a refrigerating machine following a compressor failure, it re-starts with a time delay of a few minutes to prevent a precipitous start of the compressor should the regulator activate further cooling.