Air

handling units (AHU) allow the control, by temperature and at times

by hygrometry, of the quality of delivered air.

The units are

composed of pre-made elements and assemblies in an air supply casing

and at times in an air intake casing.

Air handling units are mainly used:

- To treat fresh ventilation air to be delivered to buildings.

We

talk of air handlers or “100%

fresh air handlers”.

The

delivered air flow to air buildings is approx. 20 to 30 [m3/h]

(700 to 1050 ft3/h)

and per person.

Normally,

a fresh air ventilation unit does not deal with heating. It only

handles the heating up (and eventually cooling down) of fresh air, to

change from outside temperature to ambient temperature.

The blown

fresh air is therefore neutral from a temperature angle (it delivers

neither heating nor cooling) in relation to the treated rooms.

With

this kind of unit, heating and air conditioning of rooms is therefore

handled by another system, treating heat losses (off ventilation) and

eventually air conditioning loads. This could be a radiator circuit

or a FCU.

- To handle the ventilation and the heating (and eventually the cooling) of rooms.

Usually, the flow just for building ventilation is in general too low to permit heating (and possibly cooling). Complementing fresh air, the unit recycles exhaust air from the treated rooms. The unit is no longer “100% fresh air”.

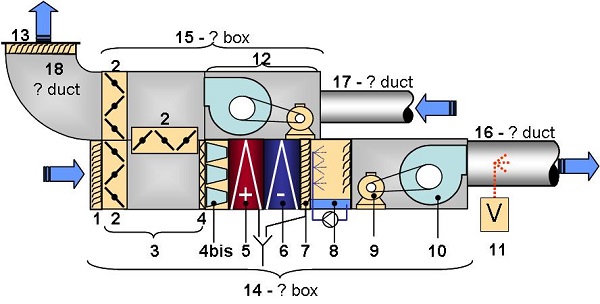

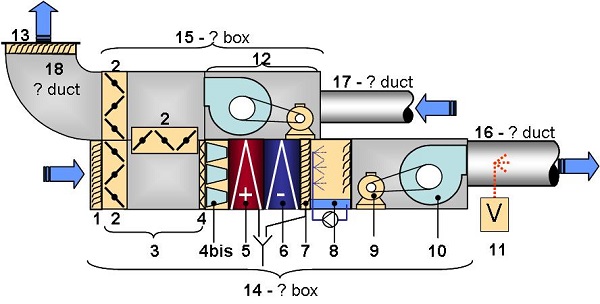

An air handling unit can be made up of:

Question

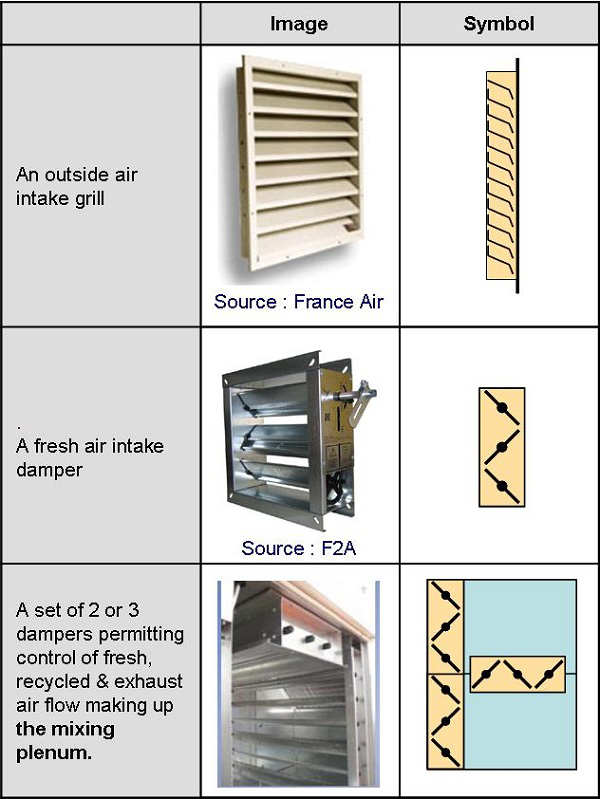

1: Fresh air intake grill

2: Dampers

3: Mixing plenum

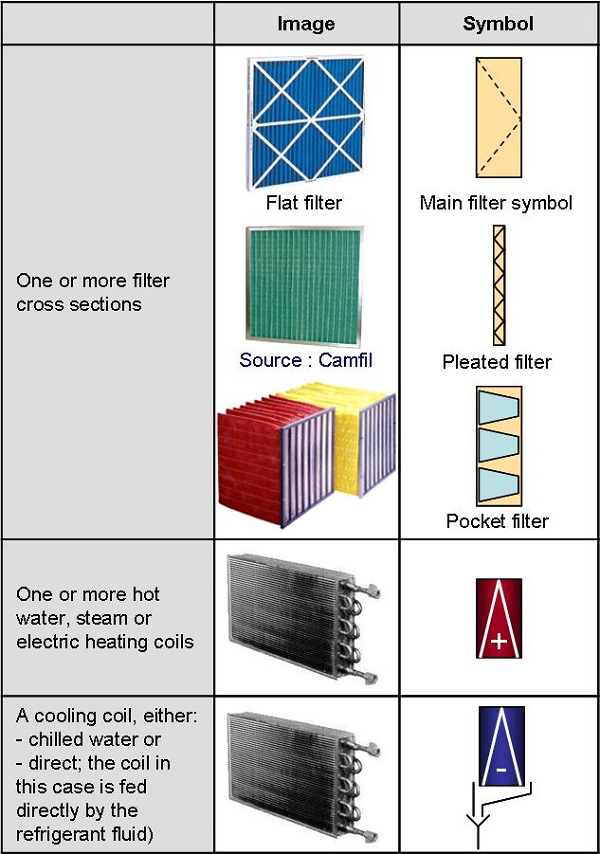

4: 1st filter row, pleated filter

4 b: 2nd filter row, pocket filter

5: Heating coil

6: Cooling coil

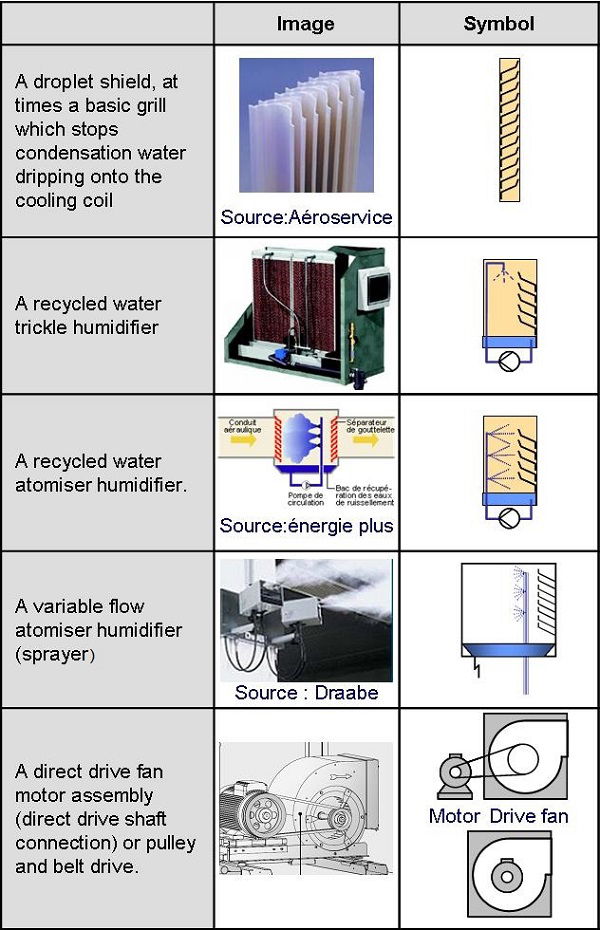

7: Droplet shield

8: Recycled water atomizer humidifier

9: Fan blower motor

10: Fan blower

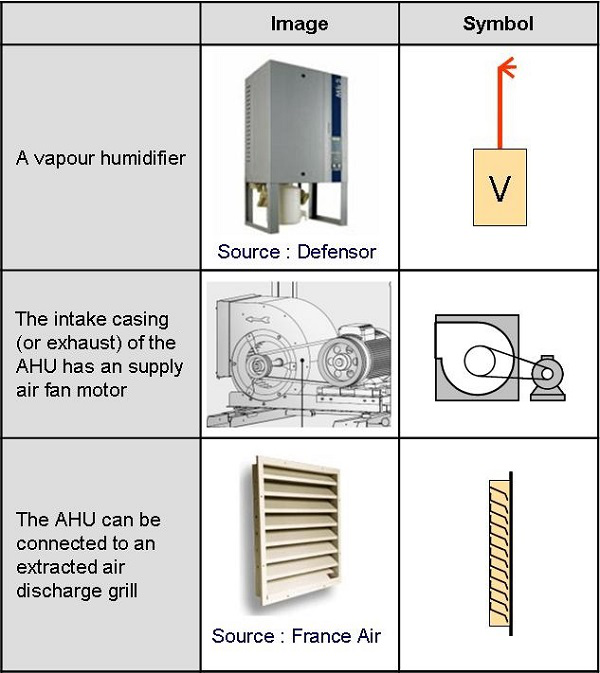

11: Vapor humidifier

12: Intake (or exhaust) fan motor assembly

13: Discharge grill

14: Blower box

15: Intake (or exhaust) box

16: Blower duct

17: Intake (or exhaust) duct

18: Discharge duct