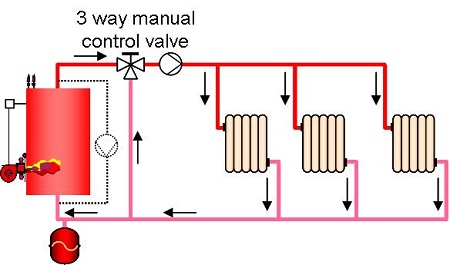

Manual

regulating of a hot water heating system can be carried out by adjusting a 3 or

4 way control valve. This allows maintaining the boiler at high temperature

under the control of its aquastat.

This is desirable or necessary for standards fuel boilers.

This « low quality » solution is un-adapted for « low

temperature » and condensation boilers because we wish to keep them at the

lowest temperature possible.

In general, we would recommend the fitting of a motorised valve piloted

automatically depending on the inside or outside temperature. However, this

fitting could, in certain cases, lead to an increase in energy consumption if

the user initially sets his manual valve in a “Spartan” manner.

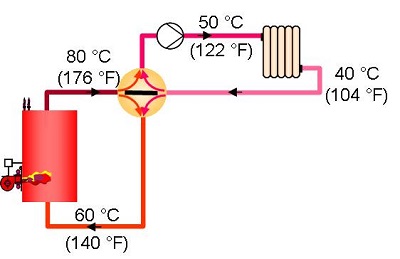

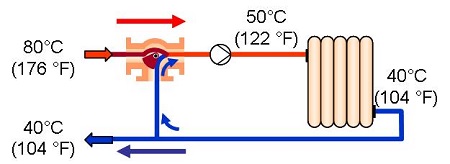

Operating principle of 3 way valves (in ‘mixing’ mode).

The temperature variation is carried out by mixing; mixing water from the

boiler with water returning from the emitters.

a) It is very cold: the water temperature is at maximum in the radiators

b) It is warm: the water temperature is at minimum in the radiators

c) In mid-season: the 3 way valve is set at intermediary

Start the film below (switch on the sound) and watch the use of a 3 way

valve on a boiler which must stay at operating temperature.

(Source : « Apprendre le chauffage à eau

chaude sur Simulateur) :

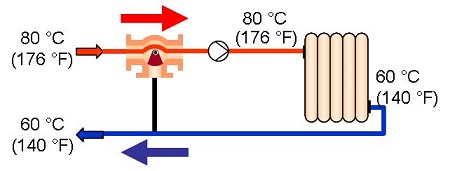

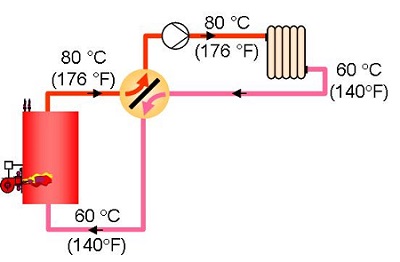

Operating principle of 4 way valves:

a) It is very

cold: the 4 way valve is fully open and the water temperature is at maximum

in the radiators.

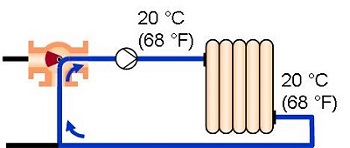

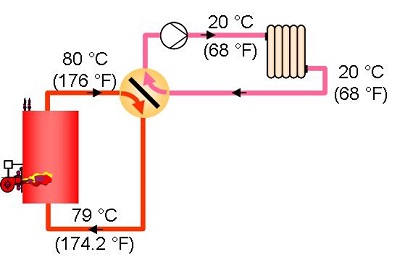

b) It is warm: the 4 way valve is “shut” and the water temperature is at

minimum in the radiators.

To encourage circulation by thermosiphon, the valve should be fitted, if

possible, one metre above the boiler and the valve to boiler return pipe should

not be insulated (obviously not ideal).

c) In mid-season: the 4 way valve is set at intermediary